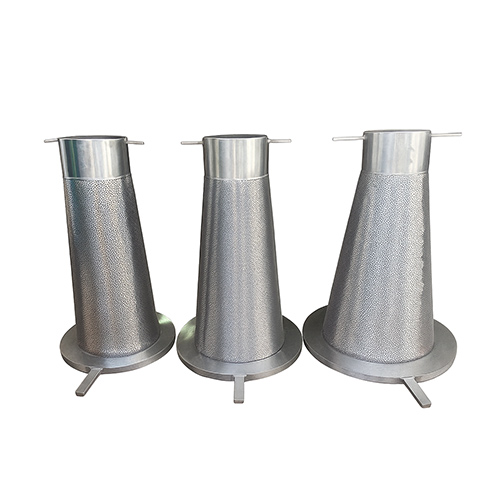

Triveni Equipments supplies Conical Strainers—also known as temporary or start-up strainers—for rapid, cost-effective protection during commissioning and early operation. Installed between flanges, the conical profile provides a large filtration area, delivering low differential pressure while capturing welding slag, rust, scale, and construction debris before they reach pumps, turbines, and control valves.

Supplied with perforated plate or wire-mesh lining, tag plates, flow-direction marking, and optional pulling eyes. Material options and QA documentation available on request.

Conical geometry maximizes screen area to reduce energy loss during start-up.

Fits between flanges—no housing required; quick to insert, inspect, and remove.

Select perforation and mesh liners for particle size, cleanliness goals, and ΔP limits.

Engineered plate thicknesses and weld quality to withstand up to ASME #2500 classes.

Material certs, weld maps, NDT, and ITP/QAP provided as per project scope.

Reusable construction lowers commissioning risk and protects downstream assets.